RG-1 Reference Motor Drive

At The Heart Of The Most Advanced Record Player In the World.

Peace of mind guaranteed

The RG-1 Reference Motor Drive is covered by a 10 year extended warranty. For the extended warranty to be valid, you must register the product with Vertere Acoustics here.

The music we hear when playing vinyl records, in reality, comes from the motor! The motor is the only source of energy in the system. It is this energy that drives the record past the stylus thus making music.

Any amount of noise or fluctuation in the drive system will adversely impact on the music. Detail, dynamics, timbre, timing and musicality are just some of the qualities that will suffer as a result.

RG-1 Reference Motor Drive with its most advanced control circuit design, implemented to its limits, allows us to achieve maximum performance from our world renowned RG-1 Reference Record Player & Reference Tonearm.

RG-1 Motor Drive takes full control of the record player motor and provides the smoothest drive with minimum noise and distortion. The music that is extracted from the vinyl unbelievably resembles the original master that the record was cut from.

Closest to the original master.

RG-1 Reference Record Player utilises a synchronous motor for its drive. Synchronous motors, unlike DC motors, can only run at one constant speed as they effectively ‘lock’ onto the frequency of their drive signal. A well-designed motor drive, can ensure a constant rotational speed.

The RG-1 Motor Drive, under development for over two years, was envisioned to match the performance of Reference Tonearm/RG-1 record player combination and realise their full performance potential.

Another requirement was to provide fine steps in speed adjustment for those records that required small speed correction. These speed errors can occur during the cutting process or could even exist on the tape. To achieve this, RG-1 motor drive, utilises a microprocessor and generates the exact frequencies that are required to drive the motor at the desired speed steps.

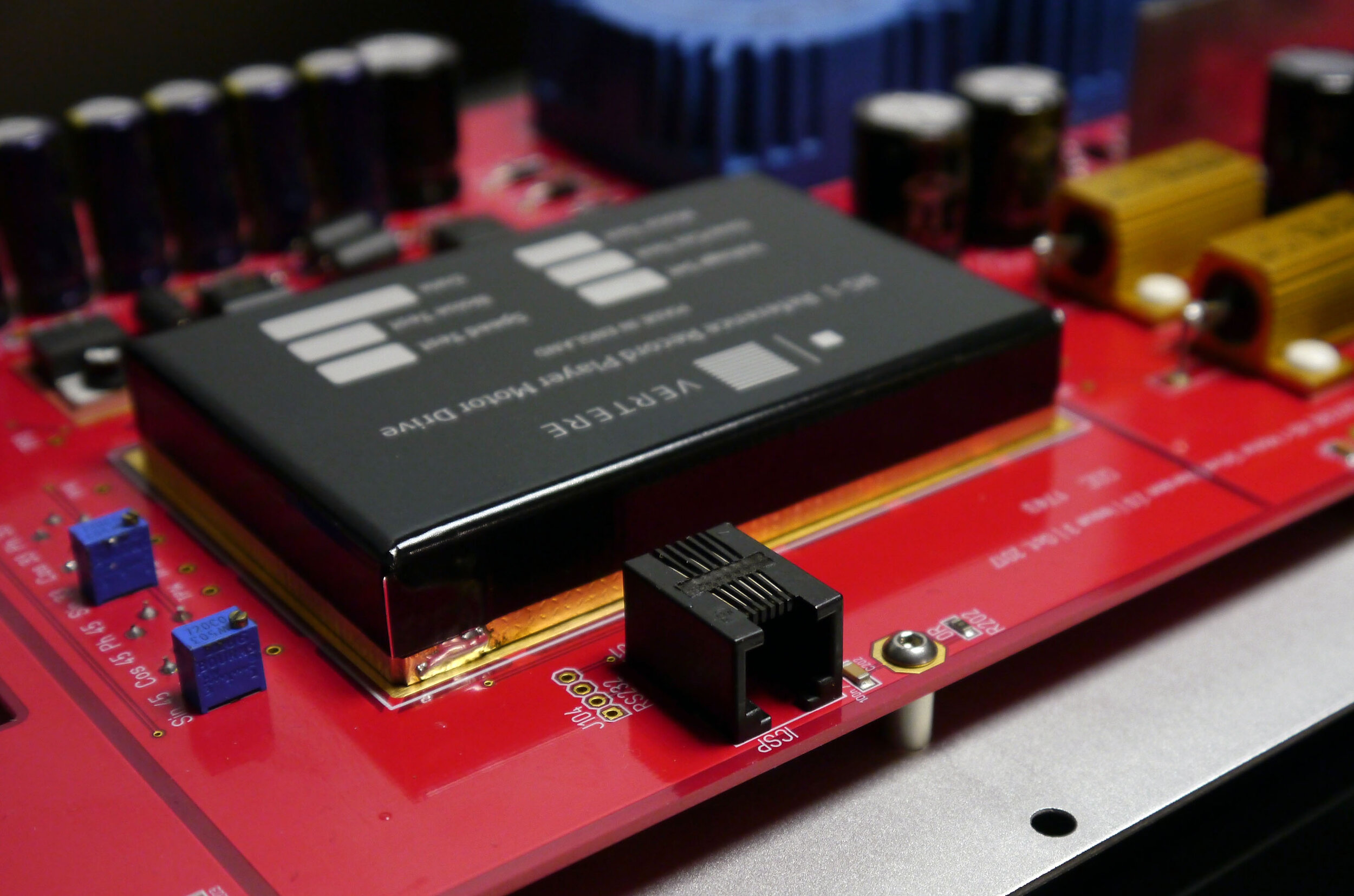

After the microprocessor, a high quality internal D to A Convertor then converts the frequencies to analogue Sine & Cosine waves that are vital for driving the motor. The Sine & Cosine waves are subsequently amplified to the required levels using 20W audio amplifiers that then drive the motor. The entire circuit and process are designed to ensure absolute motor speed stability without unwanted noise and distortion.

Fully programmable, RG-1 Motor Drive allows any necessary adjustment in order to achieve all speed steps required making it totally future proof. There are no less than three dedicated toroidal transformers to provide the power required for the output amplifiers and the different sections of the internal circuitry.

Three fully regulated and decoupled power supply rails power the microprocessor, the DAC and all the operating circuits. The microprocessor is programmable via a RJ11 on-board socket and its entire circuit is fully isolated using a solid copper shield can. Highest quality components are used to ensure the theoretical design is implemented fully and the performance optimised.

There are 7 speed adjustments via the front rotary knob allowing fine and exact ‘fixed’ speed selection of +/- 0.25%, 0.50%, 0.75%, 1.00%, 1.50%, 2.00% and 3.00% about the original 33 & 45 rpm.

There are two switches for 33/45 selection and Sleep/Operation modes. The entire mother board is mounted on an aluminium chassis and housed in a solid machined aluminium alloy cover.

Fine tuning of the residual motor noise is easily carried out from the underside of the unit.

Technical Specifications

Dimensions (D x W x H mm)

Weight

450 x 215 x 58 (including Selector & Feet )

4.1kg